Services

Single Source Rapid Prototyping and Manufacturing

As a locally-owned Single Source Rapid Prototyping and Manufacturing Center, we bring ideas to life:

One-off parts, low-run production, and complete assemblies, utilizing additive and subtractive prototyping and manufacturing processes.

-

SLA (Stereolithography)

SLA (Stereolithography)--Stereolithography (SLA) is a 3D printing process that uses ultraviolet light to cure liquid resin into solid objects. It involves a machine called a stereolithography apparatus that converts liquid plastic into solid forms, typically creating models and prototypes layer by layer.

-

Selective Laser Sintering

Selective Laser Sintering--Selective Laser Sintering (SLS) is an additive manufacturing technology that utilizes a high-energy laser to sinter thermoplastic polymer powders. The process constructs objects layer by layer by directing the laser to trace each cross-sectional geometry onto a powder bed.

-

Fused Deposition Modeling

Fused Deposition Modeling -- Fused Deposition Modeling (FDM) is an additive manufacturing technique that fabricates objects by heating and extruding thermoplastic filaments through a precision-controlled nozzle. The material is deposited layer by layer according to the geometry defined in the digital model. FDM is valued for its affordability, broad material compatibility, and simplicity of operation. Commonly used thermoplastics in this process include PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), and TPU (Thermoplastic Polyurethane).

-

CNC Machining

With over 30 years of experience, Dynamo Innovations’ CNC high precision machine department has provided exceptional service for a variety of industries.

-

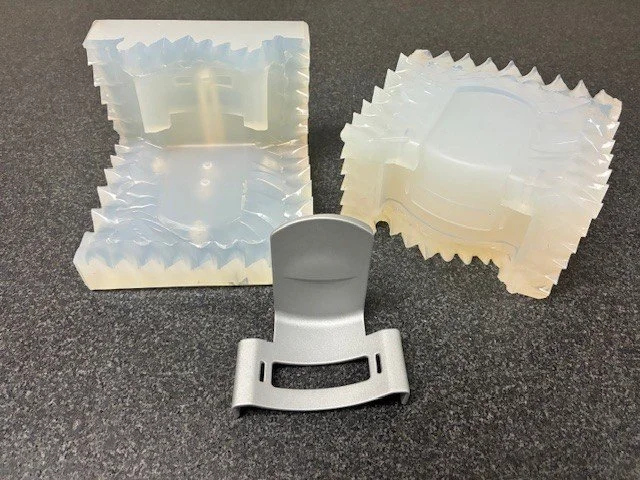

Urethane Services

Urethane Casting--Urethane casting, also known as vacuum casting, is a low-volume manufacturing technique ideal for producing custom parts. It serves as a cost-effective substitute for injection molding, making it especially suitable for prototyping, limited production runs, and specialized applications such as artistic fabrication.

-

HQ/Finishing

Dynamo Innovations’ quality and finishing department offers finishing services from simple “strip-and-ship” to full assembly “show quality capabilities.”

-

High Resolution Printing

Using state-of-the-art machinery, Scicon brings out the power of manufacturing with PolyJet, Formlabs Form 3L, Figure 4 and more.

Let’s work on your project together

With Creative Solutions, We Bring Ideas to Life

Contact us today about your next project. We’re ready to get to work.